Client: Dairy Distillery

Location: Constantine, Michigan

Size: 2.2M gallons/year

Dairy Distillery, based in Almonte, Ontario, uses a fermentation process to transform a lactose-rich dairy byproduct into sustainable alcohol. Known for their innovative Vodkow spirits, Dairy Distillery partnered with the Michigan Milk Producers Association (MMPA) to build a low-carbon ethanol plant in Michigan, aiming to reduce the dairy industry’s carbon footprint.

Dairy Distillery engaged JLR’s Industrial team to provide engineering and design services for the development of this dairy waste conversion facility. The new facility will process 14,000 tonnes of milk permeate annually from MMPA’s Constantine Dairy, converting it into 2.2M gallons of fuel-grade ethanol through fermentation and distillation processes. The resulting low carbon intensity ethanol will be sold on the market for transport applications.

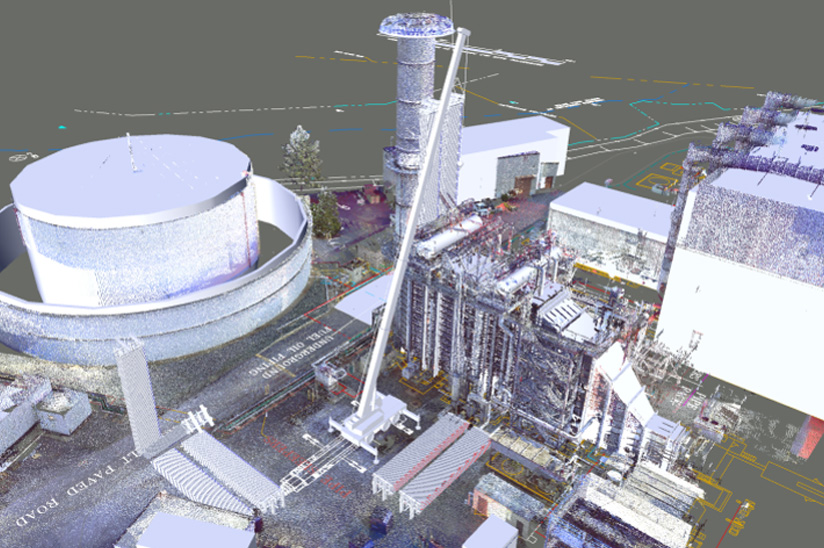

The JLR team delivered project management and engineering services across all engineering disciplines (including mechanical, electrical, civil, structural, and architectural) up to the 30% design milestone. This phase defined and documented the project scope, ensuring all major design decisions were finalized. The 30% design package enabled the client to collaborate with a US engineering firm to complete the detailed work required for professional engineering stamping in Michigan. As part of our scope, JLR developed Autodesk Plant3D and Revit models that incorporated architectural and structural building systems, industrial process mechanical and electrical equipment, as well as primary piping, HVAC, plumbing, ductwork, and preliminary cable tray routing.